Low MOQ for Instant Expanding Foam Packaging Operation - Pu foam pouring machine/Polyurethane foam packaging automatic bagging system foam-in-place machine – Zhuangzhi

Low MOQ for Instant Expanding Foam Packaging Operation - Pu foam pouring machine/Polyurethane foam packaging automatic bagging system foam-in-place machine – Zhuangzhi Detail:

Quickpack system introduction

foam packaging is a high-quality protective packaging solution that adapts to the contours of the product

and protects your goods against possible transit damage due to impact shock and vibration. Whether they’re

heavy, fragile or awkward shapes Quickpack offers the protection required for your product. Made from expanded polyurethane, the high-quality packaging foam is resistant, robust and thanks to it being light weight, reduces transport costs.

Features

Effective: Extremely impact-resistant, high cushioning

Superior foam quality: Equal cushioning with up to 45 percent less material used than alternative foam packaging systems

Robust: Effective for very heavy articles or items with sharp edges

Individual: Adapts to the contours of the product during hardening

Universal: Protects articles of almost all dimensions, shapes and weights

Versatile: Void fill, block and brace or cushion as required

Space saving: On-demand systems for minimum storage

Usage of Quickpack Expandable Foam Bags?

These bags can be used in several industries involved in the process of manufacturing heavy and odd-shaped parts. Most of these parts are quite delicate with customized structures. If any part breaks, bends or gets damaged, the entire product can get wasted.

These foam bags add optimum cushioning to prevent such damage. These foam inserts brace and block tools and parts from friction against the box packaging and stay put and safe inside

System introduction

| Item | Auto Pu foam making machine | ||||||||||

| Density | 5.1KG/M3,10KG/M3,17KG/M3,23KG/M3 | ||||||||||

Technical Parameters

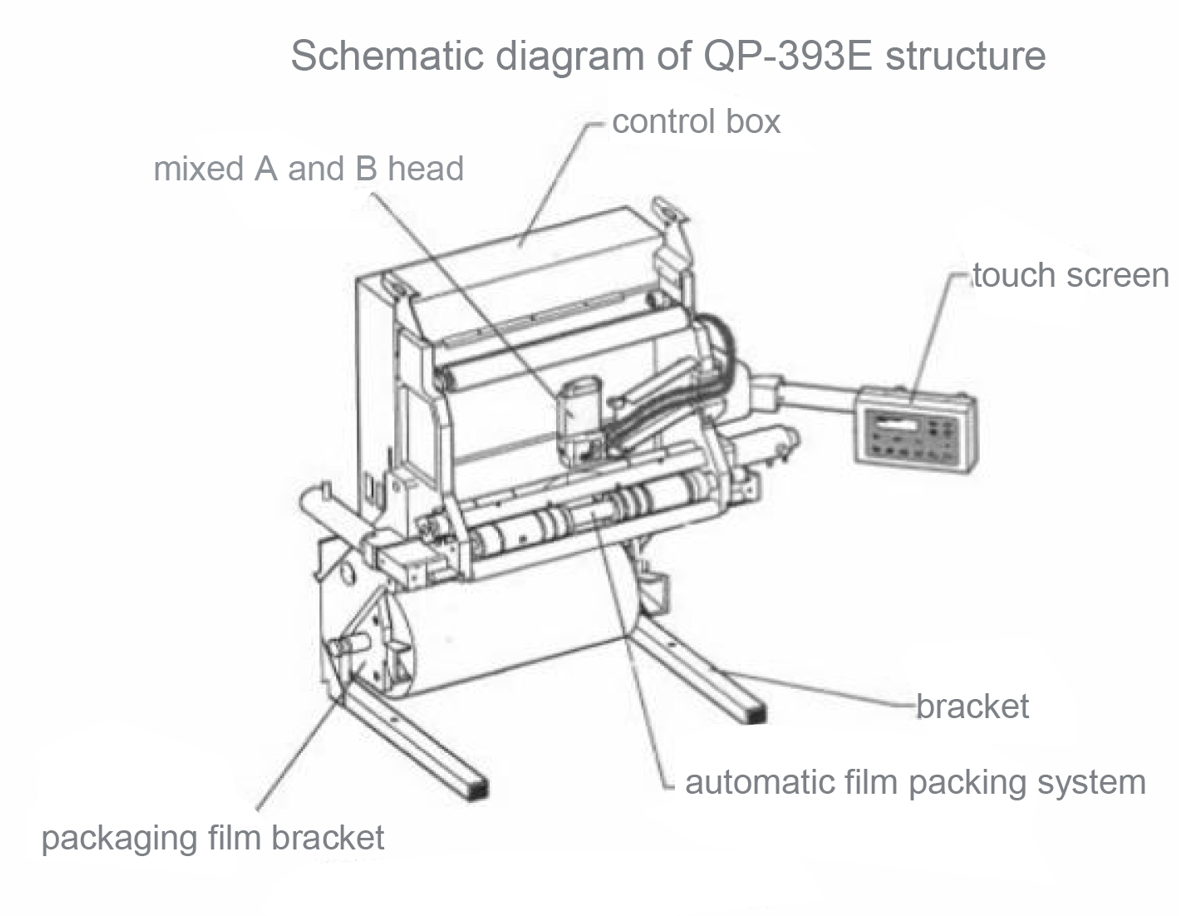

| Model | QP-393E | ||||||||||

| Power supply | 220V 50HZ | ||||||||||

| Flow rate | 4.5KW | ||||||||||

| Working area | 1.5 M3 | ||||||||||

| Weight | 145kg(net weight of equipment) Work table (27kg) | ||||||||||

| Size(Equipment and work table) | 1.2m*0.9m*2.1m | ||||||||||

| Operating Temp/Hum | Temperature: -8℃-45℃, humidity: 5%-90% | ||||||||||

| Injection time | Adjustable | ||||||||||

Product detail pictures:

Related Product Guide:

We stick with the theory of quality first, company first, steady improvement and innovation to satisfy the customers for the management and zero defect, zero complaints as the quality objective. To perfect our provider, we deliver the items together with the fantastic good quality at the reasonable value for Low MOQ for Instant Expanding Foam Packaging Operation - Pu foam pouring machine/Polyurethane foam packaging automatic bagging system foam-in-place machine – Zhuangzhi , The product will supply to all over the world, such as: Los Angeles, Sudan, Tunisia, We follow superior mechanism to process these products that ensure optimum durability and reliability of the products. We follow latest effective washing and straightening processes that allow us to offer unmatched quality of products for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

The customer service staff's answer is very meticulous, important is that the product quality is very good, and packaged carefully, shipped quickly!