Expanding foam packaging bags equipment / Quickpack protective packing materials for pu foam system

Product Video

QuickPack Expandable Foam Bags Features

Extremely impact-resistant, high cushioning.

Space saving : On-demand systems for Minimum storage.

Universal : Protects articles of almost all dimensions, shapes and weights.

Versatile : Void fill, block and brace or cushion as required.

Robust : Effective for very heavy articles or items with sharp edges.

Application

Quickpack system is best suited to small to mid sized operations that require instant custom fitted premium protective packaging.

Quickpack is a Foam In Place packaging system where two chemicals are combined to create an instant expanding foam where by an item is placed whilst the foam is still expanding which creates

Quickpack foam packaging is a simple, convenient, fully portable and compact foam in bag form of packaging that can be used for a wide variety of products offering the ultimate in protective packaging. Its unique cushioning abilities allows you to package your product of almost any size, shape or weight with a minimum amount of material but creating a custom made cushion as well as void fill and heavy duty bracing.

| Item | Auto Pu foam making machine | ||||||||||

| Density | 5.1KG/M3,10KG/M3,17KG/M3,23KG/M3 | ||||||||||

Technical Parameters

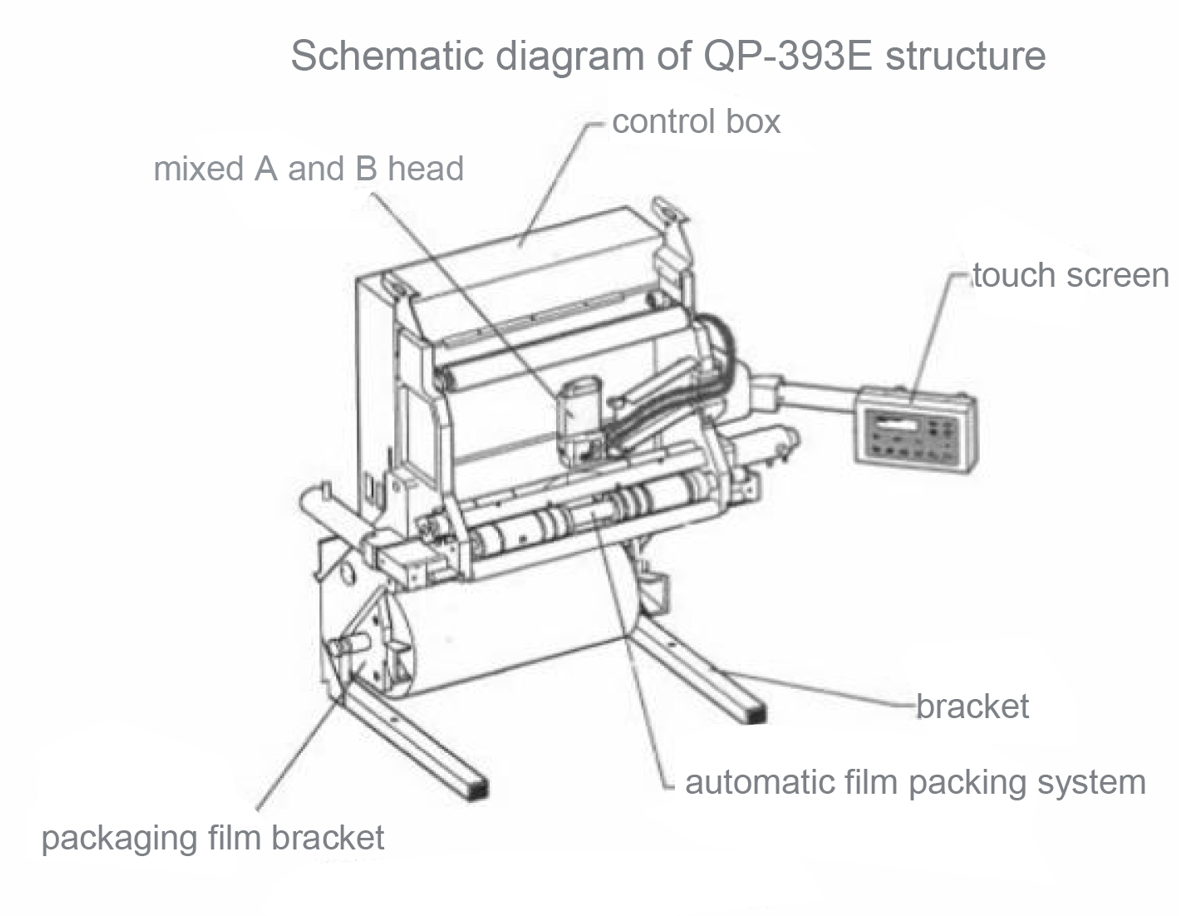

| Model | QP-393E | ||||||||||

| Power supply | 220V 50HZ | ||||||||||

| Flow rate | 4.5KW | ||||||||||

| Working area | 1.5 M3 | ||||||||||

| Weight | 145kg(net weight of equipment) Work table (27kg) | ||||||||||

| Size(Equipment and work table) | 1.2m*0.9m*2.1m | ||||||||||

| Operating Temp/Hum | Temperature: -8℃-45℃, humidity: 5%-90% | ||||||||||

| Injection time | Adjustable | ||||||||||

System introduction

Technical ParametersWe adopt the following ways to provide customers with pre-sales, after-sales service:

● In accordance with customer’s existing product packing to make value analysis.

● According to customer’s samples design, production packaging solutions.

● Detection for customers drop test , vibration test data, etc.

● For new customers to provide some vedioes training.

● Regular visit maintenance , guidance.

Maintenance of the principle of : maintenance of the main ,replacement of secondary to minimize customers maintenance costs.